In industries such as consumer electronics, automotive imaging, medical imaging, security monitoring, power monitoring systems, and aerospace, low-light imaging components serve as core components. Their performance directly impacts the stability and reliability of the entire system, particularly in low-light environments, where the performance of these components is especially critical.

1. Quantum Efficiency (QE): Refers to the efficiency with which a photodetector converts incident photons into electronic signals. Higher quantum efficiency means more effective use of photons, aiding in obtaining brighter images in low-light environments.

2. Signal-to-Noise Ratio (SNR): Indicates the ratio of signal strength to noise strength under low-light conditions, directly affecting image clarity and quality.

3. Sensitivity: Refers to the component's ability to respond to weak light signals, which is crucial for ensuring image quality in low-light conditions.

4.Dark Current: The current value output by the imaging component in the absence of light. Lower dark current results in cleaner images with fewer noise spots.

5. Response Uniformity:Consistency of the component's response across the entire field of view. Poor uniformity can lead to uneven brightness or color in the image.

6. Spatial Uniformity:Refers to the even distribution of light intensity in the image and whether there are noticeable brightness or color inconsistencies. Ensuring spatial uniformity prevents hot spots or dark areas in the image.

7. Resolution:The ability of the component to clearly display details. Higher resolution means clearer images that better reproduce fine details.

8. Linearity: Indicates whether the component's response is linear under varying light intensities, affecting the true reproduction ability of the image.

9. Pixel Defects: Includes issues like dead pixels, hot spots, and dark spots that affect the completeness and quality of the image.

10. Temperature Stability:Good temperature stability ensures consistent image quality across different environmental temperatures, especially under extreme conditions. Here's the translation:

The effective diameter not only determines the optical resolution and efficiency of the imaging system but also affects key performance indicators such as imaging uniformity, brightness uniformity, focus consistency, and optical distortion. Accurate measurement and control of the effective diameter of low-light imaging components are crucial for ensuring high performance of the imaging system. However, current testing methods still face various issues, such as insufficient detection accuracy, repeatability problems, low efficiency, low automation levels, instability of the testing light source, temperature variations, measurement errors due to angle variations, chaotic data management, and challenges in defect identification and classification.

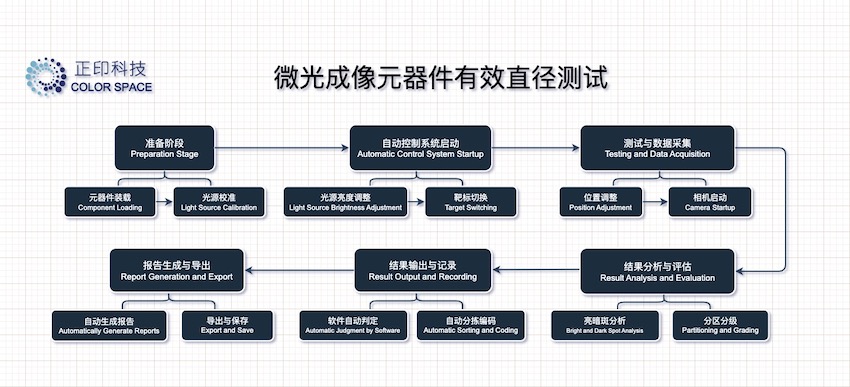

These technical problems and difficulties need to be addressed through continuous technological innovation and process improvement. The ColorSpace Rapid Extreme Cathode Effective Diameter Tester has been specifically designed to tackle these issues, providing a fully automated solution for the effective diameter testing of low-light imaging components.

Product Features:

- Efficient Automation: Fully automated control of integrating sphere light source brightness, automatic target switching, adjustment of light source and sample position, automatic sample coding and recording, loading and unloading, etc.

- Precision Detection: Real-time image capture, defect threshold and size identification, and analysis of bright and dark spots.

- Automatic Analysis: Software automatically processes detection results, performs partitioning and grading judgments, and records sorting machine data.

- Reliability and Accuracy: High-quality integrating sphere light source and fixtures, powerful software analysis capabilities.

Product Advantages:

- Increased Efficiency: Rapid detection and automated processing significantly enhance the inspection efficiency of production lines.

- Enhanced Quality: Accurate detection and analysis ensure consistency in product quality.

- Cost Reduction: Automated testing reduces labor costs and improves detection efficiency.

Industry Applications:

· Night Vision Equipment: Used for surveillance and reconnaissance in military, defense, and law enforcement activities.

· Consumer Electronics: Low-light imaging components are widely used in camera modules of products such as smartphones and digital cameras.

· Automotive Imaging: Advanced Driver Assistance Systems (ADAS) and autonomous driving rely on high-quality camera modules. Testing the effective diameter ensures that cameras provide clear images under various lighting conditions.

· Medical Imaging: In medical devices such as endoscopes and microscopes, the effective diameter of low-light imaging components directly affects image resolution and clarity.

· Security Monitoring: High-quality surveillance cameras must provide clear images even in low-light environments.

· Power Monitoring Systems: Cameras used to monitor power equipment need to accurately capture images in low-light conditions to ensure the safe operation of equipment.

Relevant Standards:

1. GB/T 14833-2009 - “Quality Inspection and Assessment of Optical Components”

For more information on related products and testing services, please contact:sales@colorspace.com.cn

Scan the code to follow [ColorSpace] to keep up with new industry news/events/solutions

Contact: sales@colorspace.com.cn

Phone: 15817270587

Tel: 400-886-3881(周一至周五 9:00~18:00)

Email: sales@colorspace.com.cn

Add: South Building #2-1101, Lv Di Qi Hang Office Building, Hou Sha Yu, Shun Yi District, Beijing, China