Infrared thermal imagers detect infrared radiation emitted by objects and generate thermal distribution maps. They enable non-contact measurement in high-temperature, hazardous, or hard-to-reach environments.

Key Features:

· Real-time thermal imaging for rapid anomaly detection

· High temperature accuracy and spatial resolution

· Non-invasive and safe testing

· Widely used in industry, healthcare, construction, security, automotive night vision, and firefighting rescue

Expanding Applications of Thermal Imaging

Originally developed for defense and night-vision operations, infrared thermal imaging is now rapidly penetrating civil markets such as autonomous driving, medical diagnostics, power inspection, and security surveillance. As adoption accelerates, manufacturers face increasingly strict requirements for image quality, compliance, and reliability.

Yet in R&D and mass production, manufacturers often encounter serious challenges: low resolution, poor temperature sensitivity, unstable images. These issues not only reduce reliability in real-world scenarios but can also result in failure to pass certification standards like GB/T 43249, leading to lost market opportunities.

To overcome these bottlenecks, thermal imaging manufacturers must establish a full-process image quality testing and calibration system that can detect hidden defects early and ensure products meet international standards.

Core Quality Challenges in Thermal Imaging Production

Image quality directly impacts downstream application safety and effectiveness. Even small deviations can cause critical risks. Below are the main pain points every manufacturer must address:

Problem

Application Example

Insufficient Resolution

Blurred details, failed object recognition

Power inspection, autonomous driving

Low Temperature Sensitivity (NETD)

Weak thermal targets undetectable

Early medical inflammation, chip overheating

Non-uniform Image

Stripes/spots distort detection

False alarms in surveillance

Slow Dynamic Response

Motion blur, delayed alerts

Automotive night vision, assembly line inspection

Temperature Drift & Stability

Biased measurement under varying environments

Vehicle-mounted or outdoor power inspection

Defective Pixels & Narrow FOV

Image integrity loss, blind spots

Dead pixels, limited coverage

Pain Point

Why Full-Parameter Testing & Calibration is Essential

From R&D verification to production quality control, each core parameter must be validated to ensure both compliance and safety.

Relevant standards include:

· GB/T 43249-2023 Passive Infrared Detection System for Vehicles

· GA/T 1708-2020 Security Infrared Thermal Imagers

· GB/T 19870-2018 Industrial Infrared Cameras

...

|

Key Parameters |

Requirements: |

| Resolution |

≥640×512 |

| Frame rate |

≥25Hz |

|

MTF 50P |

≥300 LW/PH (center) |

|

NETD |

≤ 80mK |

|

MRTD |

≤ 500mK |

|

Recognition distance |

≥110m (dummy target) |

|

FOV |

H≥24°,V≥18° |

|

Image Stabilization Time |

imaging ≤5s,stability ≤10s |

|

Thermal response time |

≤80ms |

|

Freeze frame |

<350ms |

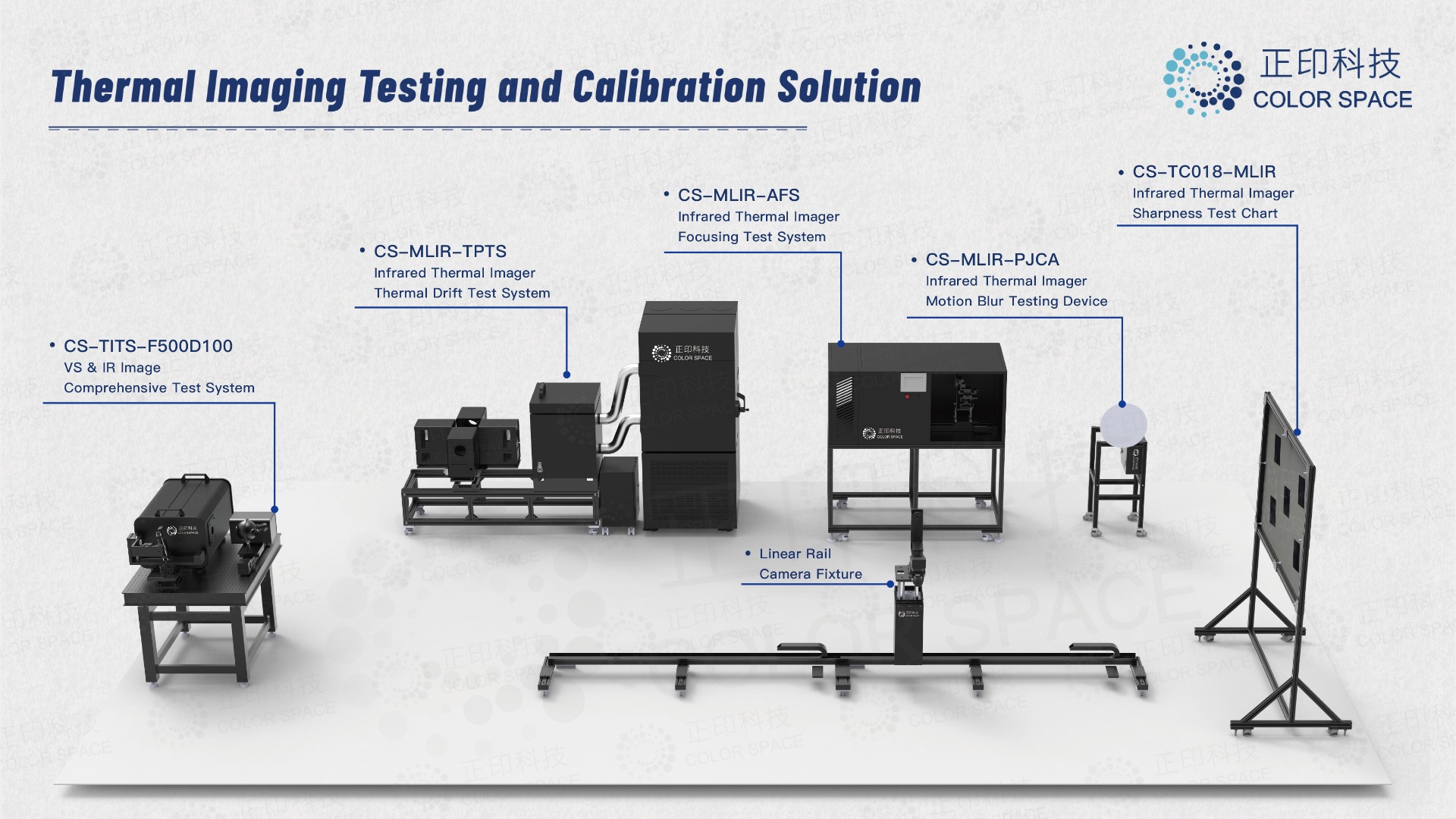

ColorSpace provides an integrated testing solution covering hardware + software + environment + service. Our systems are fully compliant with GB/T 43249-2023 (automotive), GA/T 1708-2020 (security), and GB/T 19870-2018 (industrial).

We deliver end-to-end support from R&D to mass production, addressing all pain points at the root.

Our solution includes:

Infrared Thermal Imaging Testing Solution – Configuration Table

|

Device Model |

Function & Measurable Parameters |

Illustration |

|

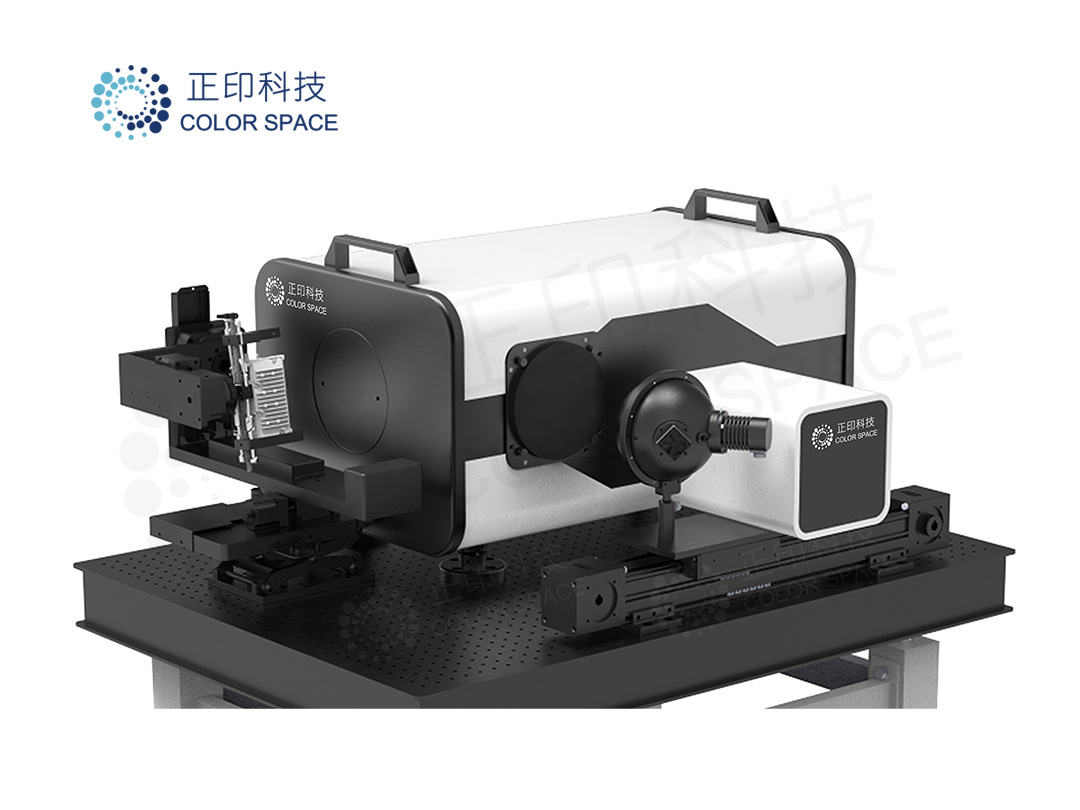

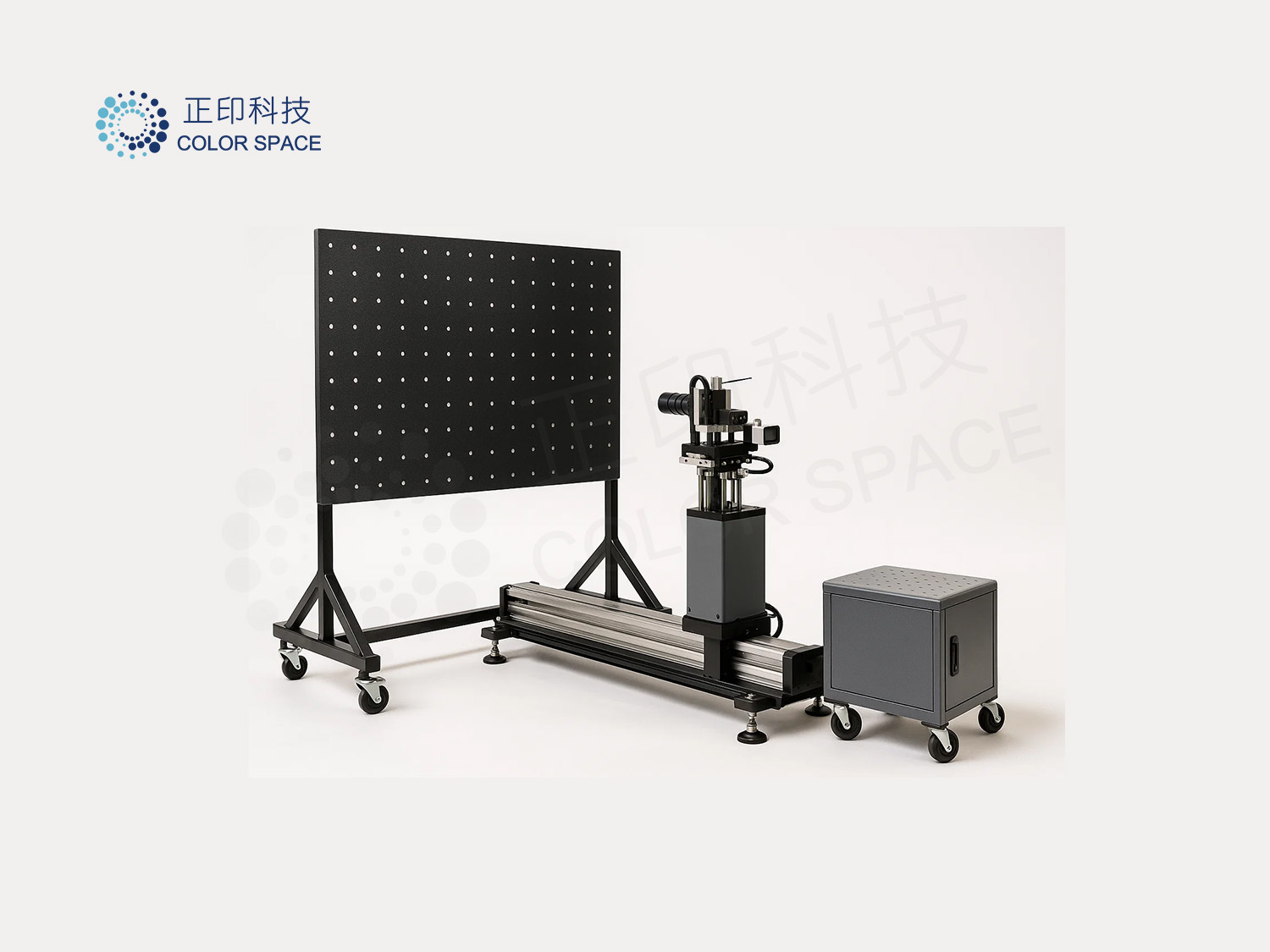

Visible & Thermal Imaging Integrated Test System

|

|

|

|

|

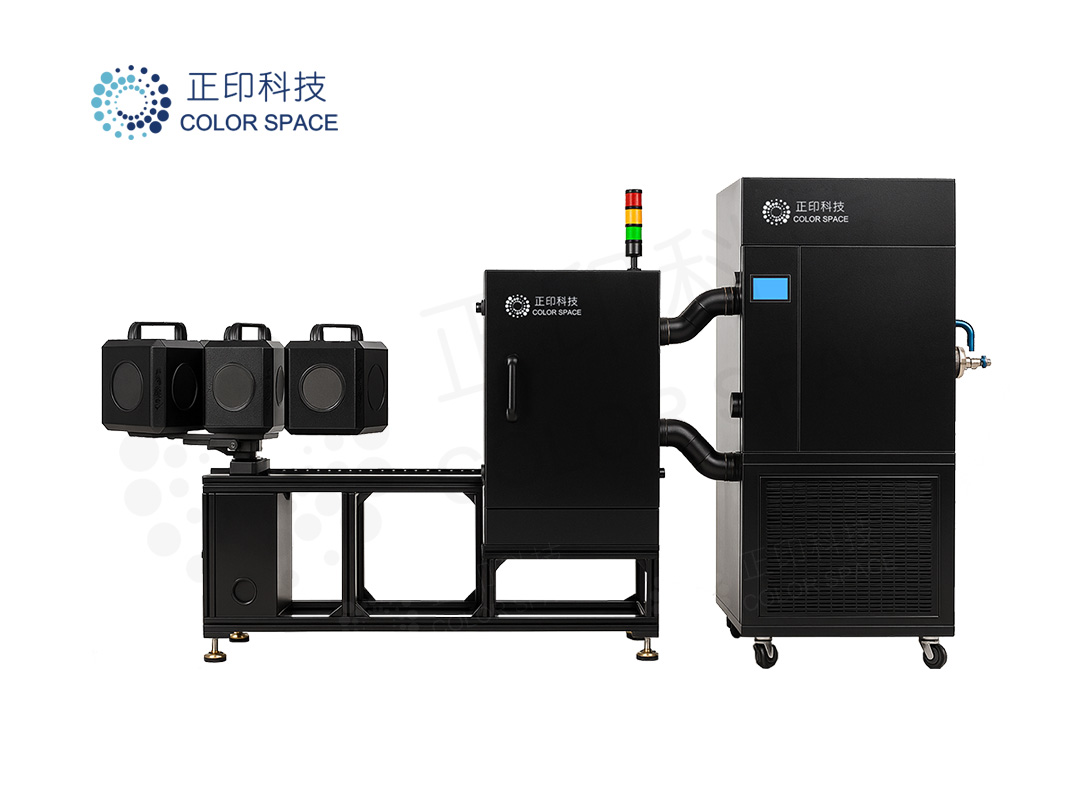

Infrared Thermal Imaging Environmental Temperature Calibration System

|

|

|

Infrared Thermal Imager Autofocus Test System

|

|

|

|

|

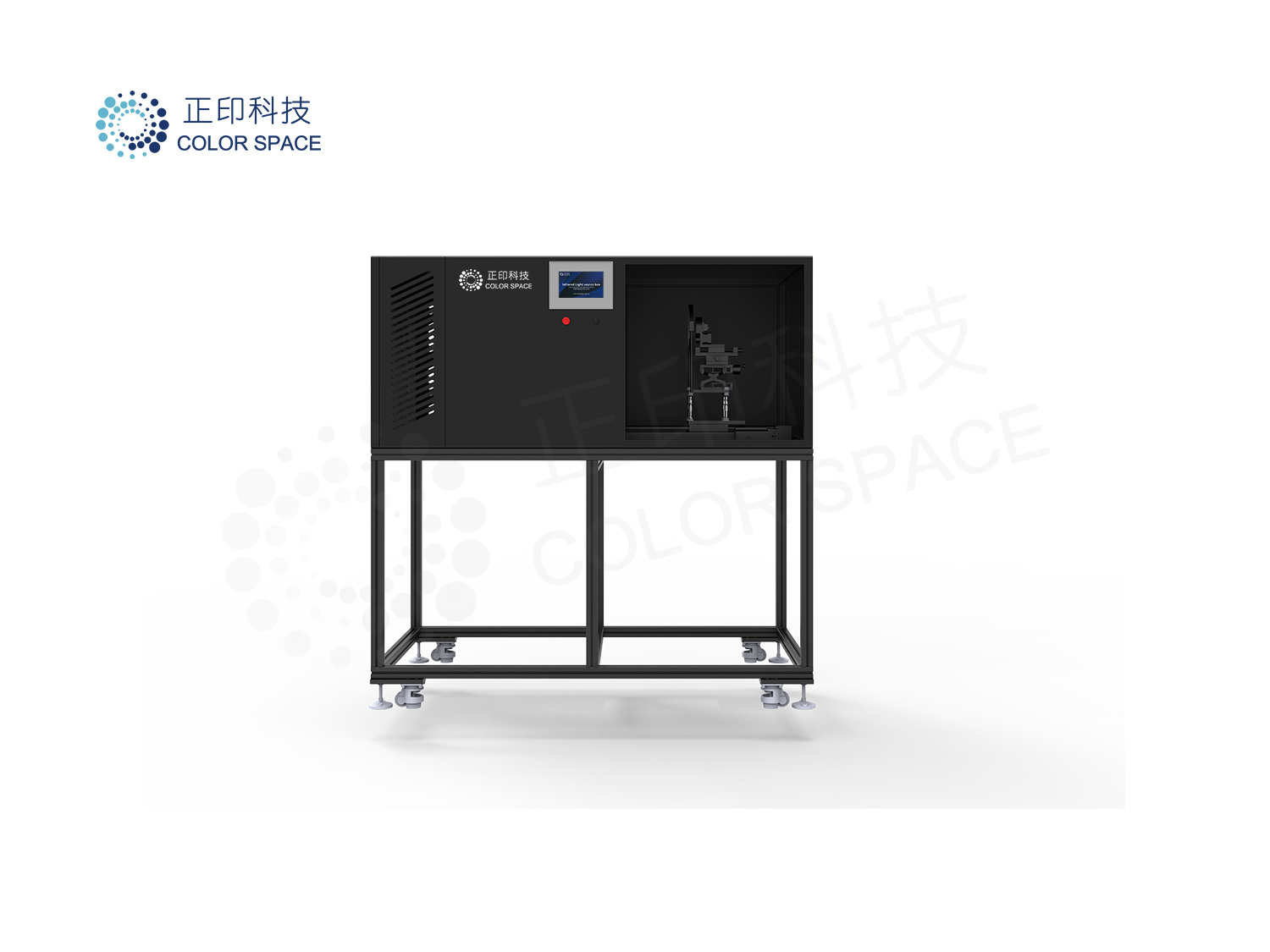

Infrared Thermal Imager Motion Blur Test System

|

|

|

Infrared Camera Intrinsic Calibration System |

Specially designed for infrared cameras to achieve high-precision geometric calibration in production lines or laboratories. |

|

|

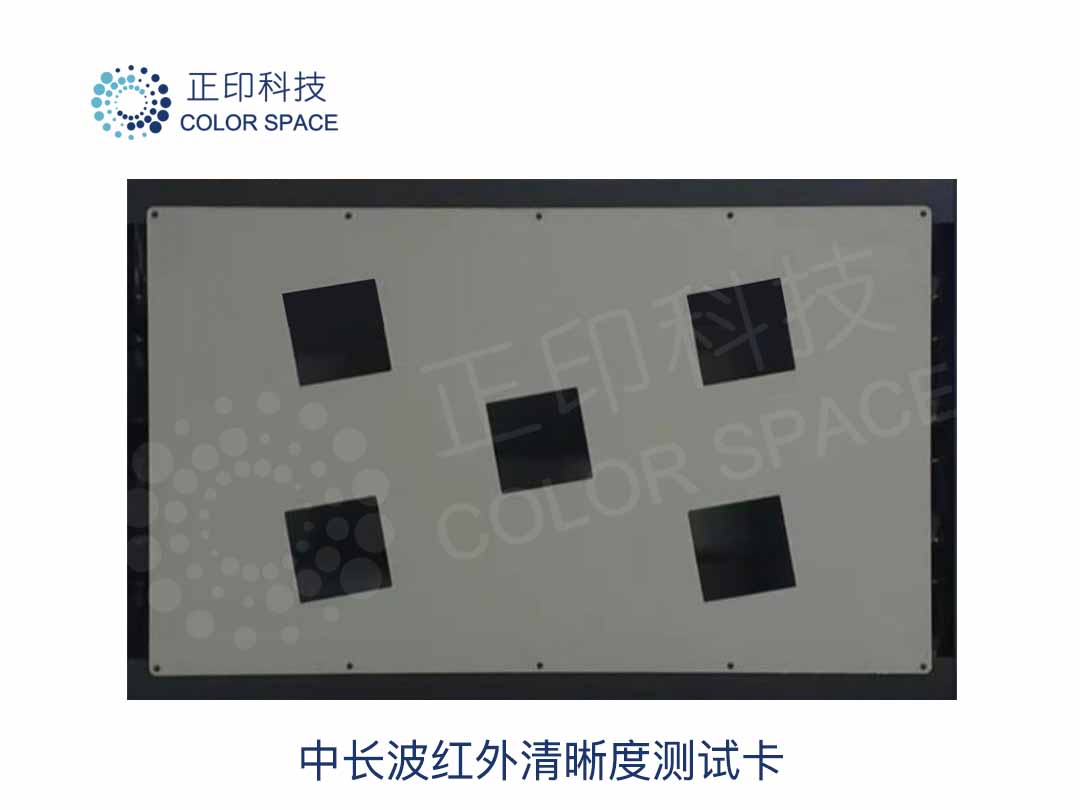

Infrared Imaging Resolution Test Chart

|

|

|

|

Image Quality Analysis Software

|

|

Full-Process Value: From R&D to Certification

· R&D Stage: Accelerate iteration, reduce trial-and-error cost

· Mass Production: Improve consistency, reduce defect rates

· Certification Readiness: Meet GB/T and international standards· Customized Services: Tailored to different industry and project needs

Partner with ColorSpace

In today’s fast-evolving thermal imaging industry, quality is the key competitive barrier.

ColorSpace’s Thermal Imaging Quality Testing Solution empowers manufacturers with reliable, compliant, and efficient testing, ensuring your products succeed in both domestic and international markets.

Request a demo, schedule a lab visit, or customize your testing plan today.

Contact us: sales@colorspace.com.cn

Follow ColorSpace for industry news/events/solutions

Contact: sales@colorspace.com.cn

Phone: 15817270587

Tel: 400-886-3881(周一至周五 9:00~18:00)

Email: sales@colorspace.com.cn

Add: South Building #2-1101, Lv Di Qi Hang Office Building, Hou Sha Yu, Shun Yi District, Beijing, China